ID.SHELFswitch –

ELECTRONIC KANBAN SYSTEM

Problems caused by manual quantity recording

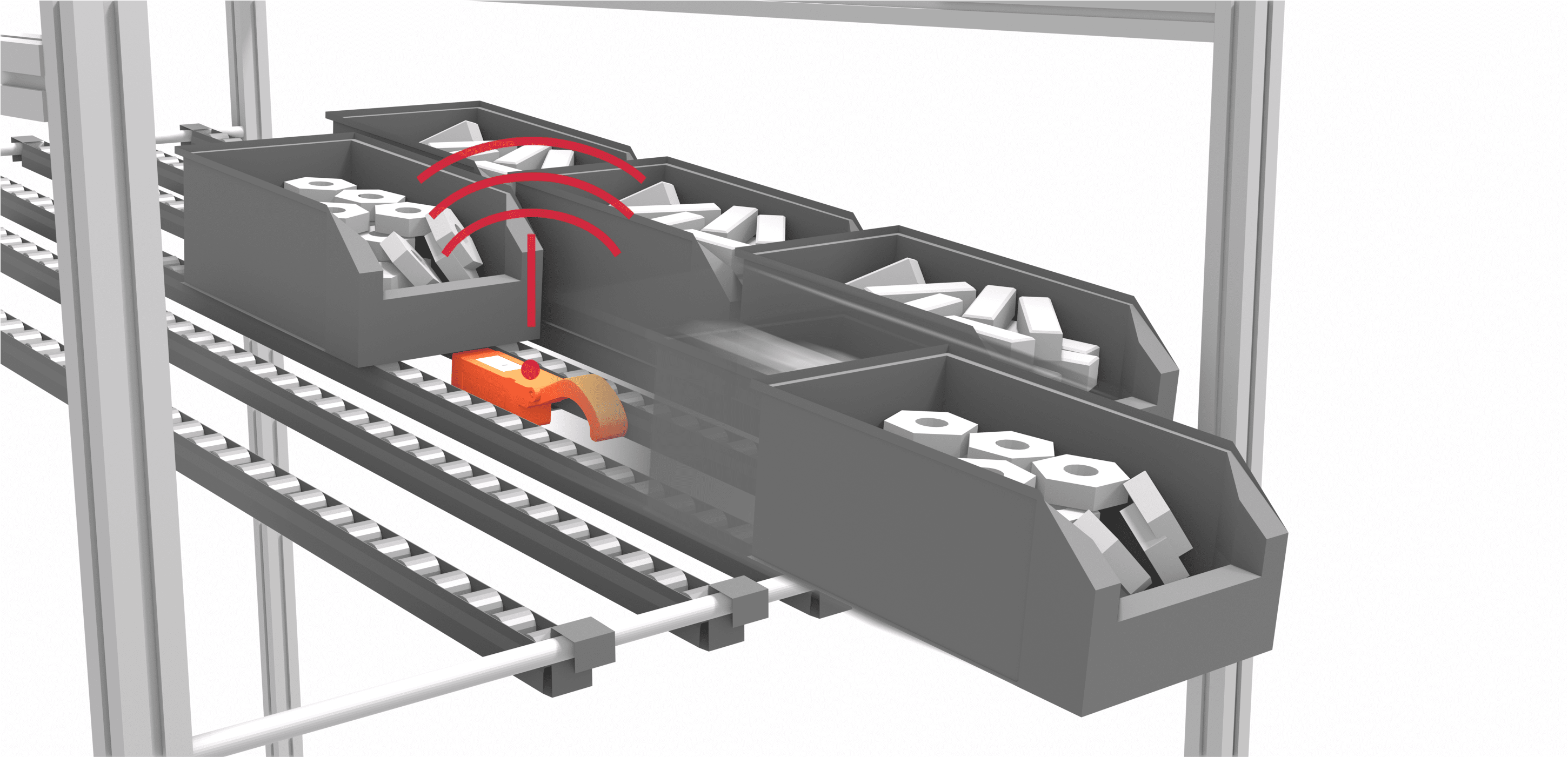

ID.SHELFswitch always checking for the presence of material. If a small load carrier is removed, ID.SHELFswitch recognizes, depending on its position in the flow rack, whether the minimum stock has been reached. When the minimum stock is reached, an order is automatically placed. The positioning in the flow rack is configured based on your needs. Both the number of containers to be delivered and the available delivery time can be stored in the system as required.

THE ADVANTAGES OF ID.SHELFswitch

[carousel_list carousel_list_items=”%5B%7B%22carousel_list_items_video%22%3A%22https%3A%2F%2Fyoutu.be%2F-EfpzhcA4EE%22%7D%5D” title=”For more detailed information about our ordering system, please also watch the videos below”]