ID.LASER – LEVEL MEASUREMENTS PER LASER MONITORING

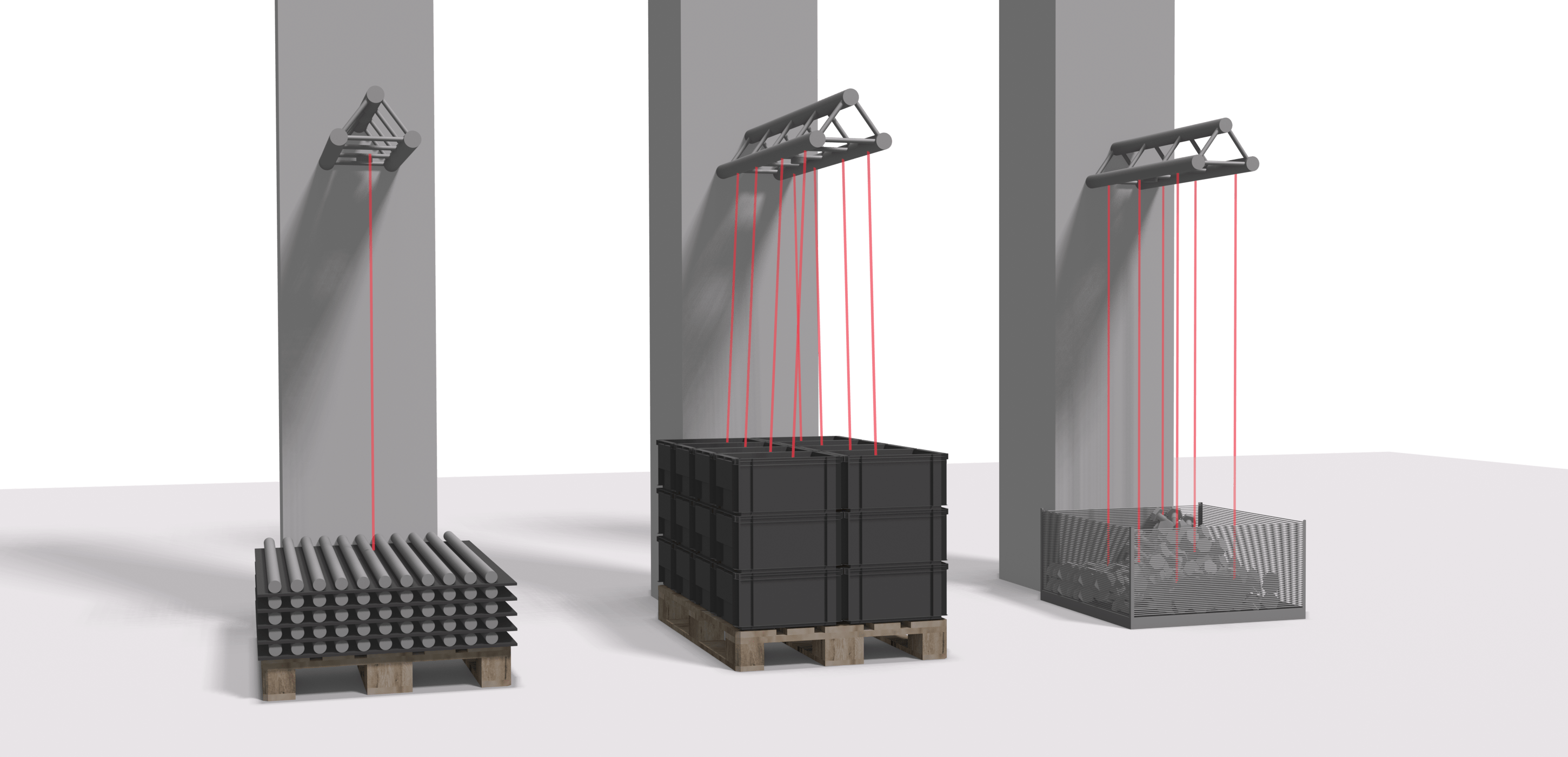

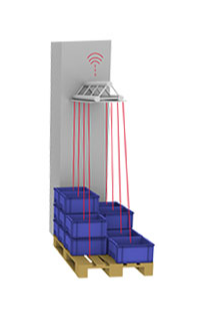

The ID.LASER from IDENTYTEC automatically detects the existence of totes, the fill levels in bulk goods and the existing layers in large load carriers. The automatic checking of material guarantees that a material replenishment order is triggered when the minimum stock is reached. Level views can be seen at any time in web-based applications on PCs and mobile devices.

When the minimum stock is reached, a material replenishment order is automatically triggered.

THE ADVANTAGES OF ID.LASER

Fully automatic material calls / fill level reports for KLT

The ID.LASER from IDENTYTEC automatically detects the positions at which containers are present and sends this information to the system.

This constant checking for material automatically triggers a material replenishment order when the minimum stock is reached.

Fully automatic material calls / level reports for large load carrier

The ID.LASER from IDENTYTEC automatically detects whether a large load carrier is available and at the same time how many layers are still in stock. This information is passed on to the system.

The constant checking automatically triggers a material replenishment order when the minimum stock is reached.

Fully automatic material retrieval / level reports for bulk goods

The ID.LASER from IDENTYTEC constantly detects how much bulk material is inside the container and sends this information to the system. When the minimum stock is reached, a material replenishment order is automatically triggered.